There is a bunch of reasons to choose a SoRoTo® Belt Conveyor. At the end of this post we’ll give you a short list of good reasons, but we will start with the details.

How long should it be? And is serial connection an option?

SoRoTo® Belt Conveyors are available in 5 lengths: 2 m, 3,3 m, 4,5 m, 6 m and 8 m.

You can use all sizes for the same purposes, but some are more obvious for some applications than others. For instance, the 2m belt conveyor is great for staircase landings, since most landings are exactly 2 m.

For many people, a combination of different lengths is optimal. With different lengths, you can create the exact length you need, and even smarter: you can get around, over and under the obstacles that might be in your way.

We’ve seen conveyor systems connected over swimming pools, through windows out of basements, used in juice bars for orange peels at festivals, and down long trails of ruby mines.

All conveyors include scaffold fittings, both in the front and in the back, for mounting on scaffold.

The fact that you have the option to serial connect and mount on scaffolding, makes it easy to put together and build a conveyor system that moves just about anything you need moved from A to B.

Standard equipment is included

A transport undercarriage with wheels is included, when you purchase a SoRoTo® Belt Conveyor. It can easily be clicked on and off, and placed anywhere on the conveyor to achieve the angle you want.

Beware: The possible angle depends on the weight and volume of the material being moved. Material, which is very light will move backwards at a large angle.

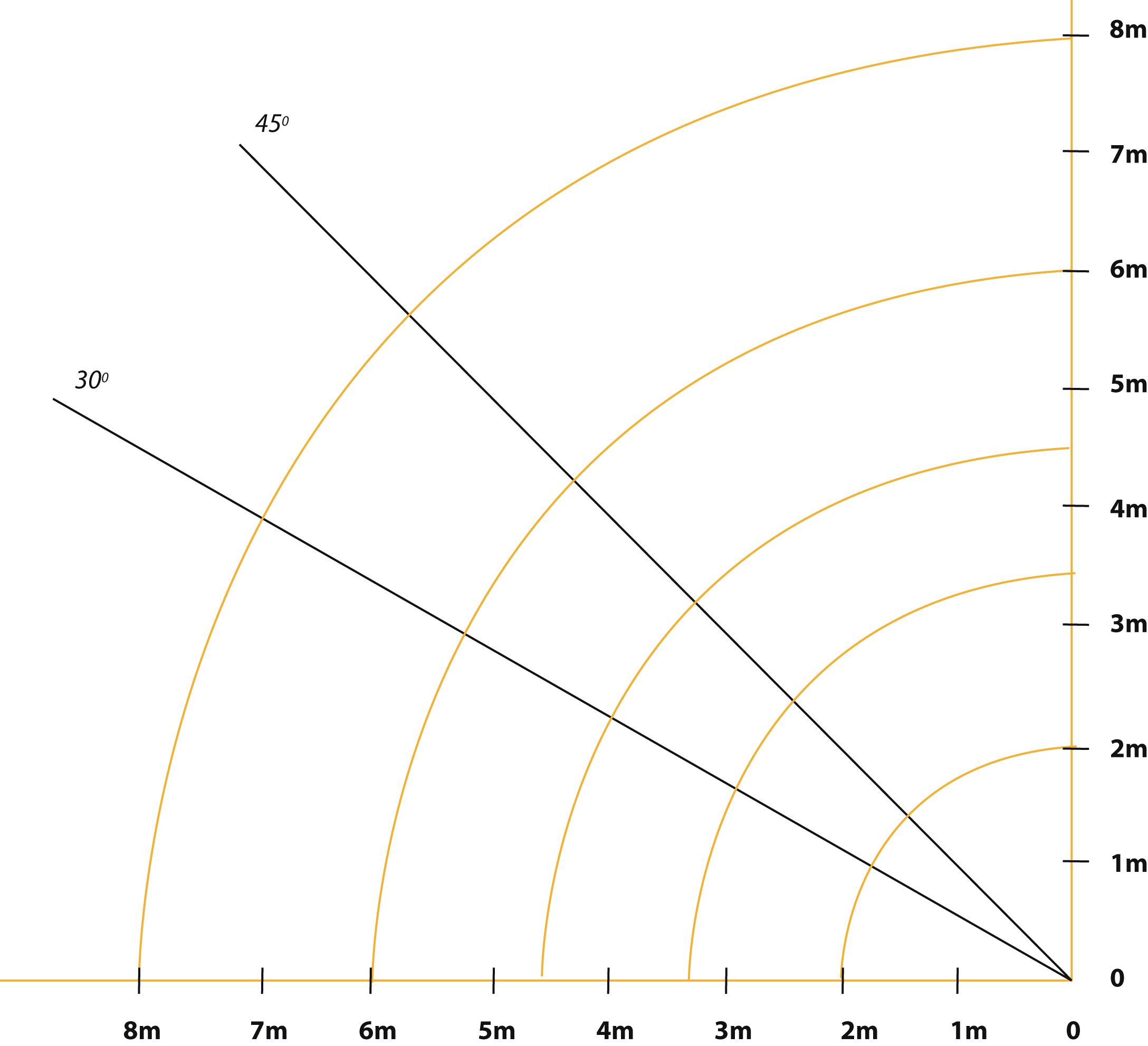

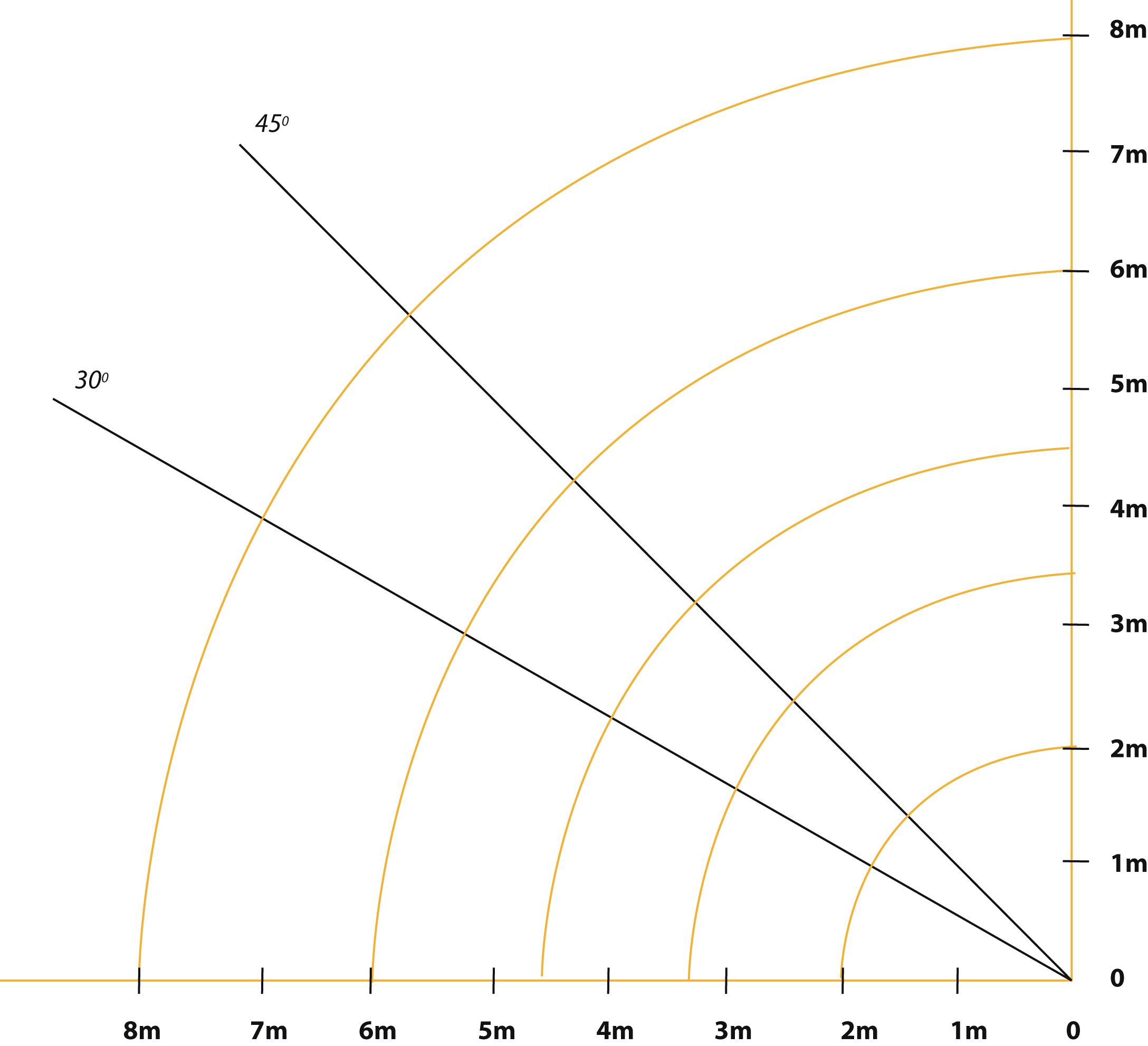

Use the diagram beneath to check whether the desired angle is possible with the length of conveyor you want or have.

The diagram shows, that e.g. both the 6m and the 3.3m belt conveyor can reach 3m in the air at 30֯ and 45֯, respectively. The question then is: What material will you move? Very light material will probably fall backwards at a 45֯ angle, but maybe it will be okay with a belt with tall carriers. Heavy and wet material will not be a problem at a large angle though.

A SoRoTo® Belt Conveyor comes complete with a standard feeder that fits most purposes. You can purchase an infeed hopper for loading with a wheelbarrow, a dumper or a mini excavator.

An open and lightweight aluminum construction

SoRoTo® Belt Conveyors are super-light. They are designed with an aluminum base and an open construction (open at the sides to, among other things, minimize the amount of heavy steel), which means that one man alone can move even the 8 m conveyor with ease.

The holes in the steel plates under the PVC belt have several advantages. They cool the machinery and belt, and also ensure the machinery partly cleans itself during operation. Dirt and filth under the belt simply fall through the holes and out through the open sides.

The steel plates are modular; replaceable in short sections. The moduls fit all sizes, so if you have several SoRoTo® Conveyors, you can have a small number of plates stored, to put on any of the belt conveyors from 2 to 8 metres.

.png)

Module 1 is the plate placed at the feeder, and the reinforced plate (module 3) is mounted on top. Module 2 is the piece that follows, and which is duplicated on the longer conveyors. The image shows the plates you need for a full 3.3 m SoRoTo® Belt Conveyor. Take a look at the Spare Parts List, page 3.

Customize your SoRoTo® Belt Conveyor

SoRoTo® Belt Conveyors are easily adaptable for different purposes.

E.g. we have many kinds of motors for the machines. The standard is a 240V/110V motor, that runs 32 cm/sec, but if needed, you can get a 400V-motor, just as you can get one with the possibility of variable speed (Vario). You can purchase a belt conveyor that runs backwards and forwards, one for extreme heat and one for extreme cold.

You can have your SoRoTo® Belt Conveyor as you wish.

322 Tons in One Day

A SoRoTo® Belt Conveyor, which is loaded with dry soil, can transport appr. 80 kg soil per meter.

The conveyor moves 32 cm/sec. If you keep loading the conveyor during a 8 hour work day, you’ll move 322 tons!

It varies, of course, with regard to the weight and volume of the material.

A SoRoTo® PVC Belt can be many things

A standard belt has 10 mm tall carriers. The carriers are small rubber strips that go across the belt with an approximate 30 cm gap in between them. They transport the material forward – and make sure that nothing moves backwards, when the conveyor is at an angle.

The standard Belt (2) fits most purposes. It is used for construction waste, soil, sand, rubble and the like.

But of course, we have other belts to choose from (see the image underneath):

Belts without carriers (1) are used for heavy and wet material i.e. wet concrete; belts with tall carriers of 30 mm (3) are for lighter materials like hay and wood chips.

If your belt conveyor is exposed to a great deal of wear and tear, there’s the option of purchasing the reinforced belt (4), which is in 3 layers and has a much tougher tensile strength.

The different kinds of SoRoTo® Belts are great for different purposes.

A SoRoTo® Belt Conveyor can be customized for almost any purpose. Among others:

- Demolition

- Construction

- Excavation

- Landscaping

- Agriculture

- Vineyards

- Scrapyards

- And much more…

10 Reasons to Choose a SoRoTo® Belt Conveyor

We boiled down the many, many reasons to 10, which you can download and print out.

Let’s not forget: SoRoTo® Belt Conveyors have been tested, trialed and developed through 25 years.

SoRoTo® Belt Conveyors are high quality products - Rough & Tough Machinery.

.png)