We get many calls about spare parts for old SoRoTo® Mixers purchased used. A SoRoTo® can last a really long time, if you care for it, clean it regularly, and adjust and change spare parts when needed (almost any part can be changed).

But you cannot know how the mixer has been looked after, and there’s quite a difference between changing e.g. the whole gear box and just changing a couple of wheels.

SoRoTo® have therefore made you a list of functions and parts to check, before you purchase a used forced action mixer.

SALESMEN OF FEW WORDS

Ads on craigslist or amazon often have little to no information. “Used mixer” can be the whole lot.

This is why contacting the salesman is a good idea, in order to avoid buying the cat in the bag. Ask for images or a video if the mixer is located far from you – otherwise go check it out for yourself. It’s always a clever idea to take a closer look, before making a purchase.

Check the general appearance of the machine and have a close look at:

- the machine in action

- the motor switch

- the gear motor and the capacitors

- the safety switch

- the mixer drum

- the mixer arms

- the welds

IS IT ABLE TO START? DOES IT WORK?

First and foremost, the machine has to be able to start and rotate. You should take a look at the electrical components on the gear motor – and you have to turn it on.

The larger 400V-mixers and the smaller 240V/110V-mixers don’t always work the same way – especially not when it comes to electrics. When this is the case, we’ve made it clear in the sections below.

The machine in use

Plug the machine in with a cable of max. 10m. It must be all rolled out. The longer you let the machine run, the better – and it’s even better if you can put some material in the mixer drum to see how it operates. If possible, use wet gravel or another heavy material.

As the machine runs: Does it sound right? Does it rattle? Does it smell weird? If it does, we advise you to check where the sound or smell come from?

Do the mixer arms turn as they should? If you’re dealing with a 240V/110V-mixer (40-120L), lift up the mixer system to see, if the spring pins are straight, and if they are all 4 there and undamaged.

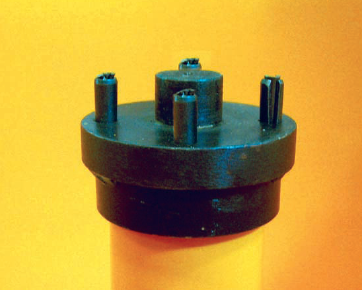

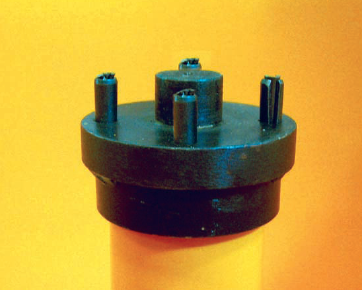

The drive shaft on a 240/110V-mixer.

On the yellow image, the 4 spring pins

are apparent at the top of the shaft.

The spring pins (2 pcs. on old machines, 4 pcs. on the new ones) are made to bend or snap when the mixer arms meet unusually great resistance. This is to keep the gears from overloading or break.

If you only have 2 spring pins on your drive shaft, it’s easy to drill new holes for an extra 2. You don’t have to, but 4 pins together are stronger than 2 pins – and if you buy new mixer arms, they have 4 holes for the spring pins.

HOW TO: Change your spring pins

If the spring pins are okay – or you’re dealing with a 400V-machine (which has a different mixer system and no spring pins) – and you can turn the mixer arms with you hand, it’s either because the drive shaft is no longer fixed in the gears (something is broken, in other words) or because the tongue fell out of the groove in the gear box.

Call your local SoRoTo® dealership for help.

If the machine does not turn on, check our FAQ: My forced action mixer won’t start…

If the machine runs smoothly, there are no weird noises from the motor switch or the gear motor, and the capacitors do not smell, all the electrical components should be alright.

Are you ever in doubt, you should give us a call, and we’ll guide you in the right direction.

The motor switch

The motor switch is the black or grey box next to the gear. It’s the box, on which you turn the machine on or off, and where you plug it in.

Inside the motor switch, there are a thermal fuse and a ”motor protection switch”.

These make sure that the machine turns off, if it is overheated for some reason.

It can happen if there are not enough Amperes on the fuse, if the cable is too long, if it is not properly rolled out, or if something is stuck in between mixer arm and drum (i.e. old concrete) and the machine therefore has to struggle to try and turn the arms.

The Motor switch is an integrated unit, which means, it is purchased ”all inclusive” as seen on the images to the right.

If none of the above seems to be the issue with your machine, you should check the safety switch.

The safety switch

Does the safety switch work?

When the grid lid is opened and you get access to the drum, the safety switch should turn off the machine, so it stops turning, and you do not risk getting you fingers or anything else stuck between the shovels and the drum.

The safety switch is a legal requirement in most countries – for your safety.

If the safety switch doesn’t work, you should try to adjust it.

See how to adjust the safety switch.

We’ve had two different kinds of safety switches on the SoRoTo® Forced Action Mixers. On the images below, you can see what they look like. The image has the old one with the push button to the left, and the new one with the arm to the right.

You can easily get and mount both.

The old safety switch to the left, and the new one to the right.

The gear motor and the capacitors

The gear motor is the mixers’ heart, and the capacitors make sure that the gear motor runs, runs properly, and keeps on running.

BEWARE, the 400V models do not have capacitors. They do, however, have a phase turner, that you should remember to check every now and then.

See how to check and adjust the phase turner.

The SoRoTo gear motor is developed to deliver maximum effect and minimum strain – on the power grid, on the environment and on the wallet.

- The starting capacitor (100-125 uF) sparks the engine.

- The drive capacitor (25/40 uF) ensures that the gear motor keeps going when started up.

- The phase capacitor (20 uF) makes sure that the other capacitors keep working.

On some of the older machines, the capacitors have other Mikrofarad denominations (uF). Take a picture and send it to us, if you’re in doubt.

To be safe, do check the capacitors for dents or other deformities and smell. If they are deform or have a smell of burnt plastic, they HAVE to go, otherwise you risk they do more damage than good. You can easily obtain and change them.

As seen on the image below, the capacitors are placed on the outside of the motor now. If you need a new capacitor, but you don’t know which one, please take a photo of it, and send it to your local SoRoTo® Dealership.

The capacitors have been placed in different places through time, but don’t worry. We can help you figure out, which one you need.

If possible, check if the mixer has the same data as a new machine would. Look at the nameplate and the appearance. If the mixer has been tampered with, it can be difficult to find spare parts that work.

THE GEAR MOTOR

The gears are the top part, which is fastened in the drive shaft.

The motor is below the gears.

The capacitors are the black tubes placed outside on the motor.

On some of the older mixers, the capacitors sat on the inside of the motor.

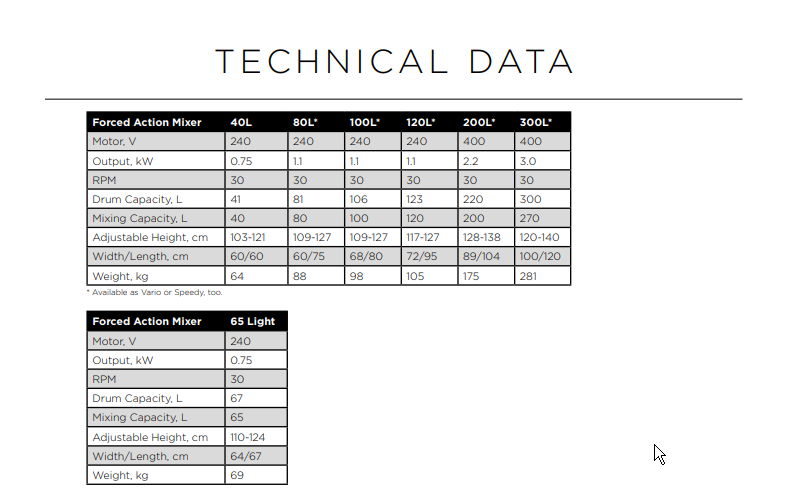

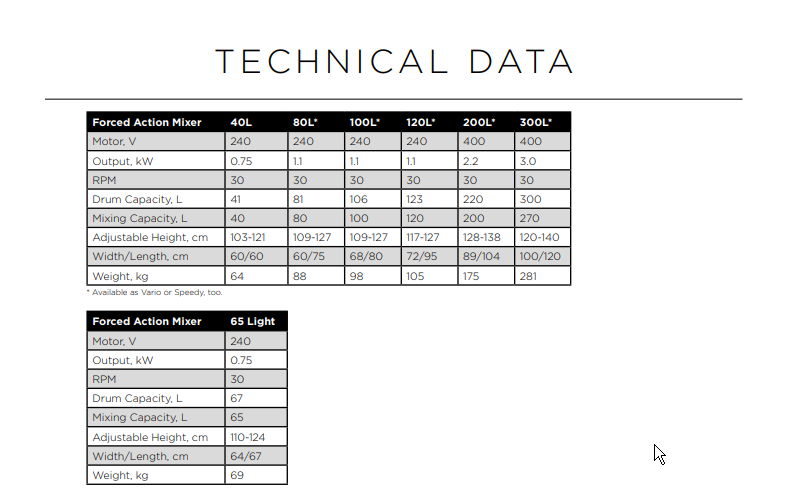

You should investigate or ask the salesman: how many Volts the machine runs on, and how big the output is. You can find and print the data sheets on our website. They are on the last pages of our catalogue – this way you can easily check the data, and make sure that everything is as it should be.

WELDS, ADJUSTMENTS…

Does the drum leak? Do the mixer arms follow the sides and the bottom of the drum? If the machine is badly kept, has been cleaned by knocking forcefully on the drum with a hammer, or if something has been stuck between the drum and the shovels. It could have caused deformities of the drum, and made the welds loosen.

Drum and mixer arms

The mixer arms can be adjusted, and you can change them one by one. So if they are fairly worn down, or they don’t seem to sit where they should, it is not the greatest problem.

Please make sure to check the reason why the arms are worn down or crooked. If it is something apparent and easy to take care of.

A clean mixer drum ensures that e.g. the wear and tear of the mixer arms is reduced, and they therefore last a lot longer.

It is not wise to cut down on maintenance. For every single time you skip the cleaning after mixing, it will get even harder the next time.

QUALITY MIXES

need optimal conditions within a quality machine.

This is why clean, well-adjusted mixer arms are important

– as well as a drum where sides and bottom are kept clean

and clear of old, hard material.

For the most part, the mixer arms are worn down because they encounter hardened material in the drum – or because the drum is deformed.

The mixer drum can become deformed, if the machine has fallen down violently, e.g., or because it has been cleaned with a hammer.

Learn how to maintain your mixer.

If the machine has been mixing material containing aggregates using steel shovels, the shovels and the drum can be dented or worn down or thin.

Should you be using steel or rubber shovels?

OTHER

Finally we’ll touch upon other topics, that are nice to know.

OIL

You can change oil on the mixers. When we send a machine out the door, we make sure it’s filled with oil for life – but if the mixer for some reason gets turned on its head, oil leakage is unavoidable, and a refill is needed.

How to change the oil.

SPARE PARTS

We innovate and evolve all the time. Among other things, because of EU-restrictions and injunctions, but mainly because we’re eager to be ahead of the development within the industry – and because the possibilities to make our customers’ work lives easier, become more and more.

We always try to make sure that new parts can be used for older machines as well, to ensure that you can use your machine for years and years, even though you have to change a wear part from time to time.

If you’re in doubt about your machine’s age:

On the plate to the right of the motor switch (where the serial no. is also located), all the data on the mixer is. This is where you find the date when the machine was reported as finished.

Make sure to get the receipt for the machine. This way, you’ll know when it was purchased, and you can be sure it wasn’t stolen.

Spare parts for older mixers are therefore almost always possible to get. You can buy them from your local SoRoTo® Dealership.

Check our FAQ or call your dealer if you’re ever in doubt about needing a new or old part – or anything else.

CE-RESTRICTIONS

If the machine is bought as an old model, the CE-restrictions might not be the same as for the new machine.

As a rule, a safety grid has to be placed at the top (the grid lid) and at the bottom (the safety grid by the discharge chute). The restrictions changed a lot through the 90s, and they will continue to change in the future. The latest change was in 2017, when we introduced a new safety grid.

If you’re ever in doubt which rules apply in your district or in your country, please don’t hesitate to contact the local authorities on this matter.

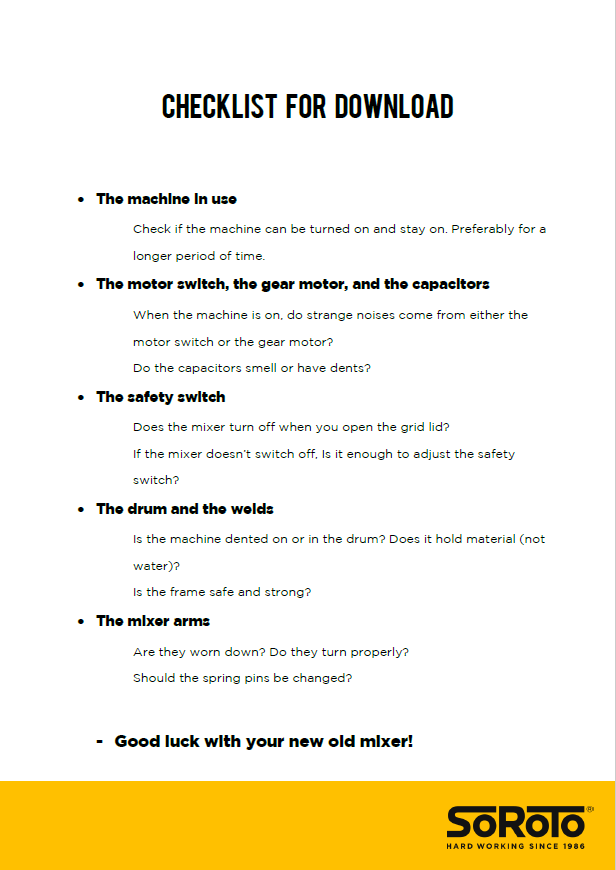

Click on the image below to download the checklist